Basis

Project Overview

Create a promotional product that represents APDesign and can be produced in-house.

6 Weeks

Individual Project

Spring 2025

Create a promotional product that represents APDesign and can be produced in-house.

6 Weeks

Individual Project

Spring 2025

APDesign:

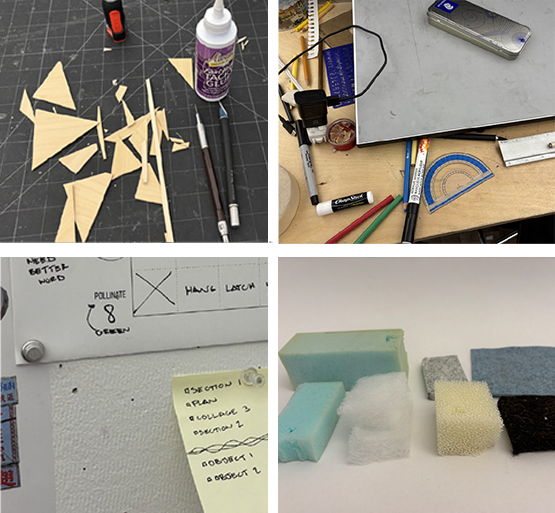

Every student goes through the first year course ENVD where utility knives are used frequently.

Most students lose the cap to their utility knives and also do not use the blade disposal because it is

more convenient to stick blades into foamcore while working on a project.

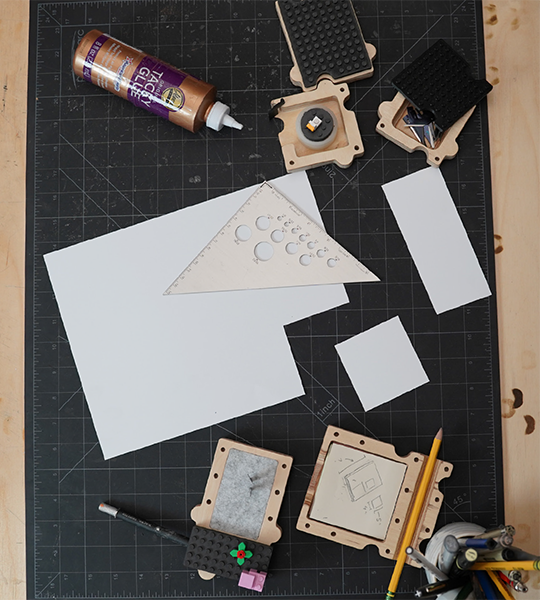

Many scrap materials are left in the shop and can be utilized for in house production.

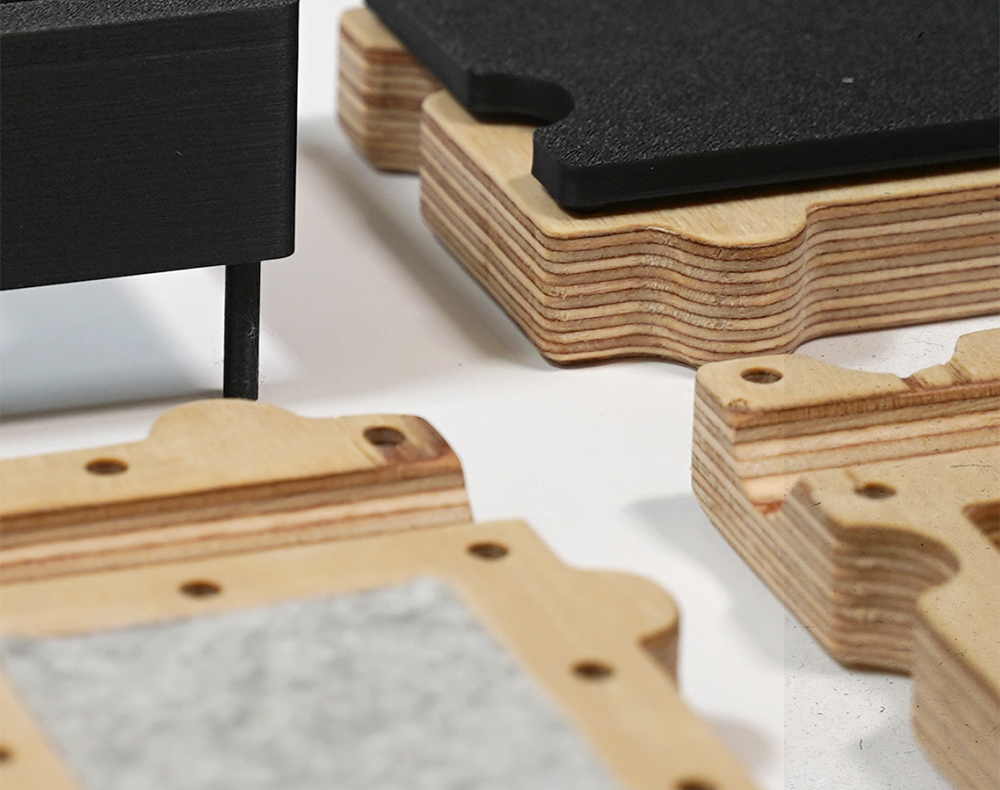

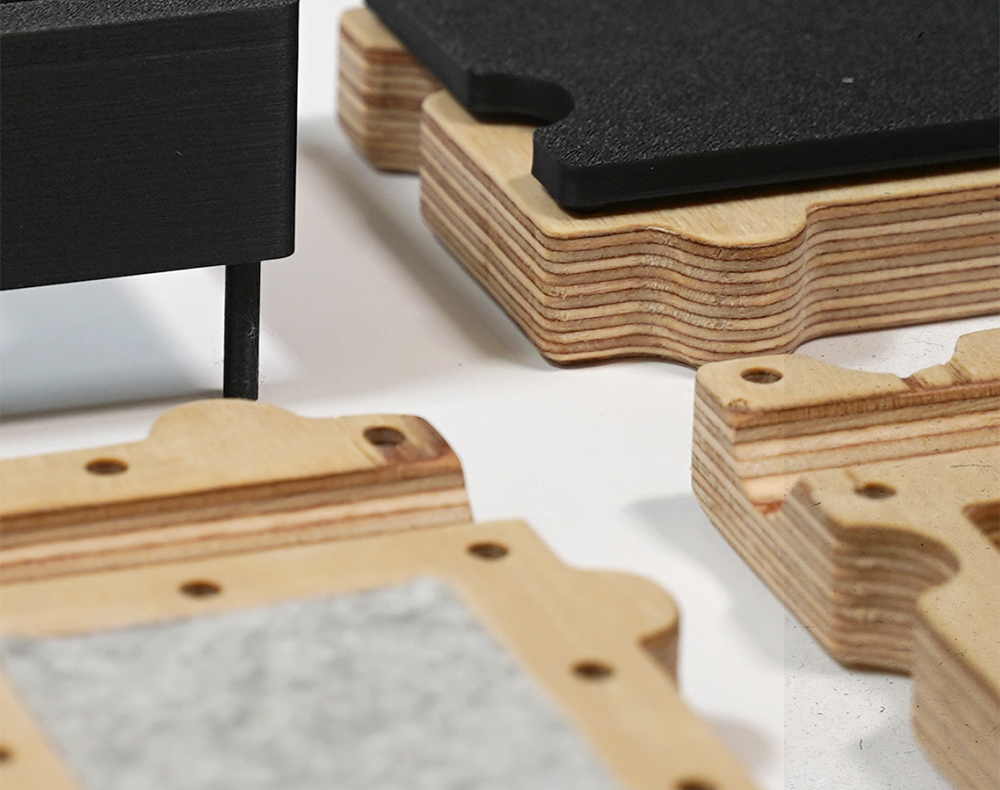

While exploring materials I found various types of foam. The grey acoustic foam held up well to

blades piercing it and held them in place too.

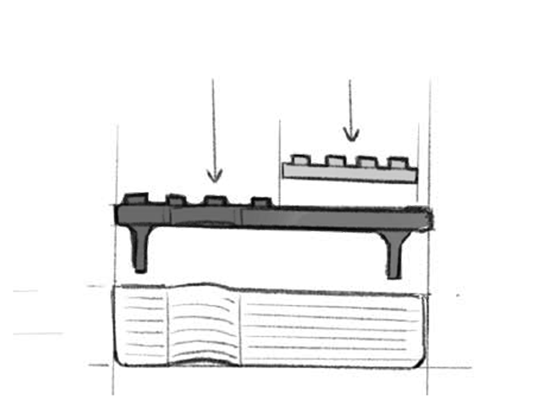

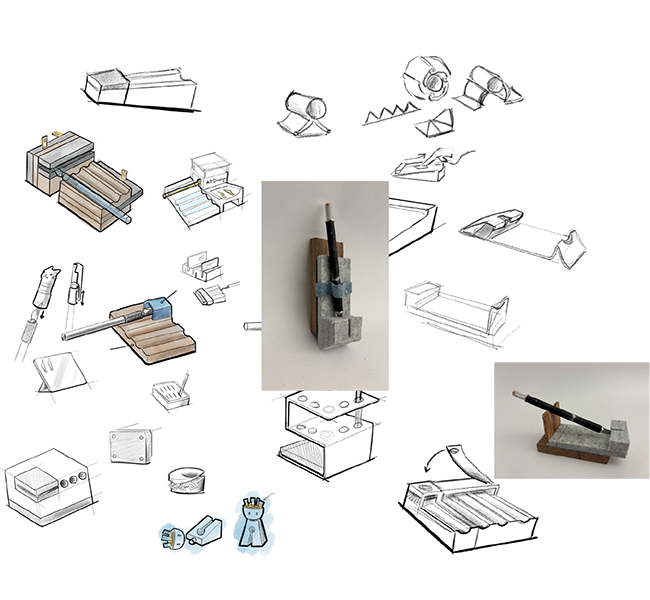

How deep should pockets be to lift sticky notes and writing/cutting utensils?

What kind of tolerance and shape is needed for the best alignment and fit?

How should the 3D printed files be designed to prevent breakage and print well?

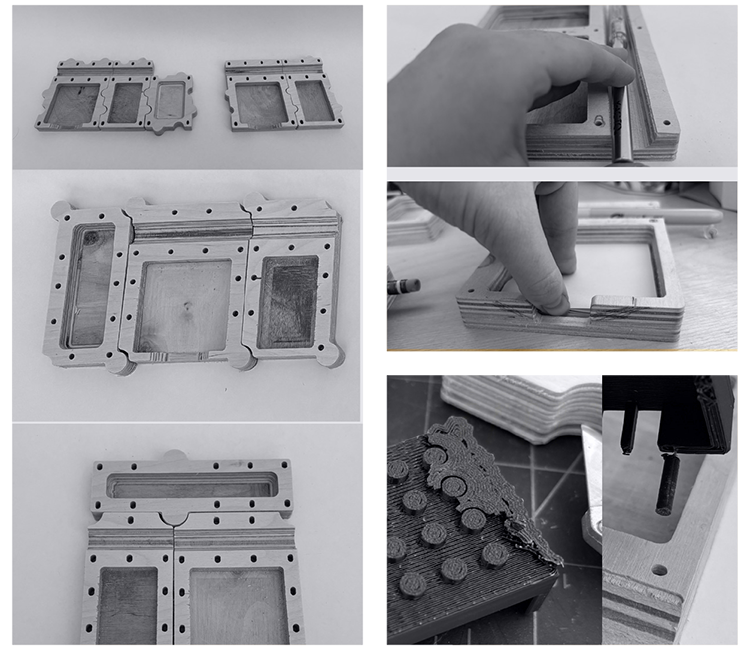

The plywood base was CNC cut and then chiseled out of the material. They were sanded,

routed, and applied wipe-on polyeurathane to finish.

The acoustic foam had to be hand cut on the bandsaw.

CUT

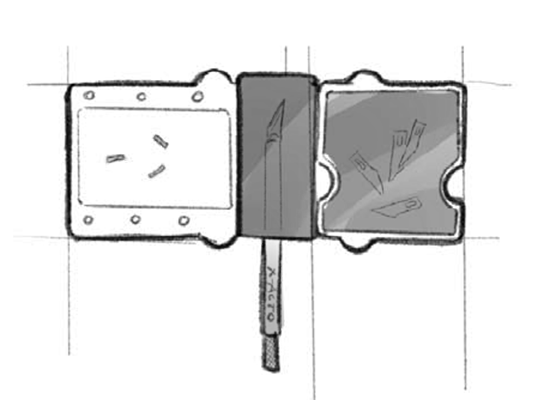

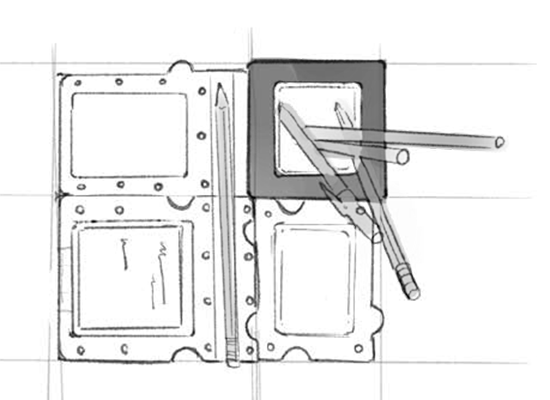

Cover exacto knives and store new blades or temporarily rest dull ones.

RECORD

Store sticky notes and writing utensils.

ORGANIZE

Easily align and configure to suit your needs.

BUILD

Add covers, additions, and even build again with legos.